How do we make an outboard corrosion-resistant?

In saltwater, corrosion protection really matters to the service life of your outboard. Normally, there are two types of corrosion that could happen on your outboard. They’re chemical corrosion (a metal material exposed to the wet or humid environment) and electrochemical corrosion (a surface contact between two metal materials). To make every Spirit truly corrosion-resistant, we have adopted multiple designs and techniques.

Prevent Chemical Corrosion

1. Base material

The first step is always about choosing the right base material. So we build the lower unit housing, clamp and the shaft, where chemical corrosion goes often, with aerospace aluminum alloy. When aluminum surfaces are exposed to the atmosphere, a thin invisible oxide skin forms immediately, which protects the metal from further oxidation. This self-protecting characteristic gives aluminum its high resistance to corrosion.

2. Protective coating

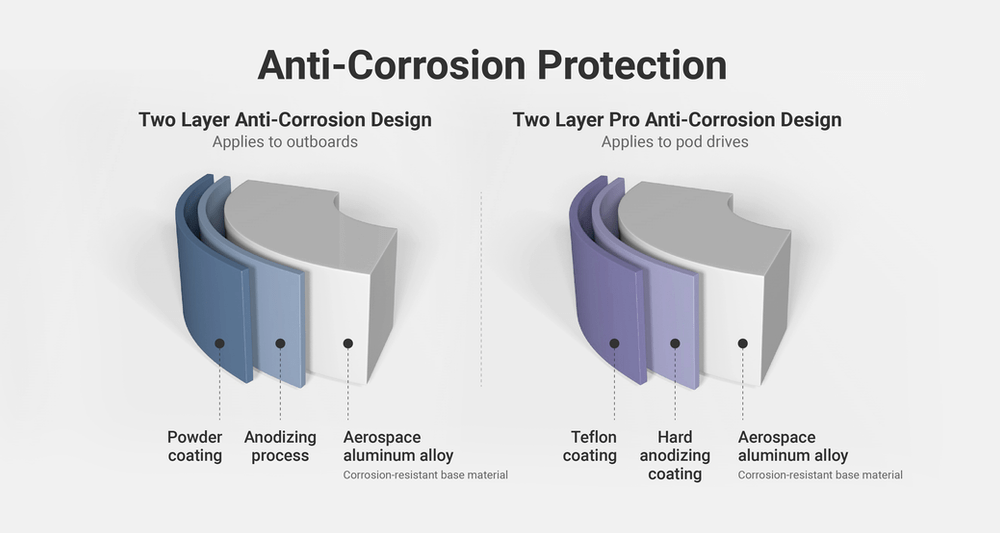

The coating is like providing body armor to the base material. It brings better corrosion-resistant performance. On the aluminum alloy, we use a anodic oxide coating first and then its powder coated. So there are two protective coatings. In addition, on the lower unit housing and the clamp, a sandblasting process is done to clean the substrate and create a surface that will hold the two protective coatings better.

ePropulsion pod drives and Spirit 1.0 RS21 drive require more corrosion-resistant protection. We have hard anodic oxidation coating and Teflon coating to replace the normal anodic oxide coating and the powder coating. So they can stay in the saltwater for many years without being corroded.

3. Metal connector

To improve the connector durability, Spirit 1.0 Plus features a metal connector between the power cable and the battery. The base material is stainless steel, and we adopt a PVD (Physical vapor deposition) processing to the connector. PVD coating is harder and more corrosion resistant than coatings applied by the electroplating process. So after hundreds of times connecting and unplugging, the metal connector can still be corrosion-resistant.

Prevent Electrochemical Corrosion

There’re sacrificial zinc anodes on every outboard. That’s the basic anti-corrosion method. On Spirit 1.0 Plus, you will find 4 pieces on the clamp and the lower unit.

Two Tips

1. An outboard is not supposed to be immersed in water for a long time. You should tilt it up after each use. If you use it in salt water, rinse it with fresh water after each use.

2. Avoid any scratches that could hurt the base material. If any scratches or paint loss caused by a collision, contact your dealer for inspection. It’s necessary to do damage control and repair before it goes worse.

If you have any questions regarding corrosion protection, contact a local dealer or reach us on our official Facebook page.